Understanding Wax Crystallization: A Comprehensive Guide

In the world of waxes, one phenomenon that can significantly impact their performance and properties is crystallization. Wax crystallization refers to the process where the molecules within a wax transition from a disordered, liquid state to an organized, solid crystalline structure. This phase change can have profound effects on the texture, appearance, and behavior of the wax, making it crucial to understand and address crystallization in various applications.

What is Wax Crystallization?

Wax crystallization occurs when the temperature of a wax drops below its crystallization point, causing the molecules to align and pack together in an ordered, repeating pattern. This process is driven by the inherent tendency of molecules to minimize their energy state and achieve a more stable configuration.During crystallization, the wax molecules undergo a series of structural rearrangements, forming crystalline regions within the material. These crystalline regions act as nucleation sites, promoting further crystal growth and propagation throughout the wax matrix.Types of Waxes Susceptible to Crystallization

While all waxes can potentially undergo crystallization, certain types are more prone to this phenomenon due to their chemical composition and molecular structure. Some common waxes that are susceptible to crystallization include:- Paraffin Wax: Derived from petroleum sources, paraffin wax is composed primarily of long-chain hydrocarbons, making it highly susceptible to crystallization.

- Beeswax: This natural wax, produced by honeybees, contains a complex mixture of esters, hydrocarbons, and fatty acids, which can lead to crystallization under certain conditions.

- Vegetable Waxes: Waxes derived from plant sources, such as sunflower wax, rice bran wax, and candelilla wax, can also experience crystallization due to their diverse molecular compositions.

- Rosin-Based Waxes: Waxes containing rosin (a natural resin derived from pine trees) are particularly prone to crystallization, as the rosin molecules can readily form crystalline structures.

Factors Influencing Wax Crystallization

Several factors can influence the rate and extent of wax crystallization, including:- Temperature: Lower temperatures generally promote faster crystallization, as the molecules have less kinetic energy and are more likely to align and pack together.

- Cooling Rate: Rapid cooling can lead to the formation of smaller, more numerous crystals, while slower cooling may result in larger, fewer crystals.

- Impurities and Additives: The presence of impurities or additives in the wax can affect the crystallization process by acting as nucleation sites or inhibiting crystal growth.

- Agitation and Shear: Mechanical agitation or shear forces can disrupt the formation of crystalline structures, leading to different crystal morphologies and properties.

Consequences of Wax Crystallization

Wax crystallization can have significant implications for various applications and industries, including:- Cosmetics and Personal Care: Crystallization can alter the texture, spreadability, and appearance of wax-based products, such as lipsticks, balms, and hair care products.

- Candle Making: Crystallization can affect the burn performance, scent throw, and overall quality of candles made from waxes prone to crystallization.

- Lubricants and Coatings: Crystallized waxes may exhibit different lubrication properties, adhesion characteristics, and protective qualities compared to their non-crystalline counterparts.

- Oil and Gas Industry: Wax crystallization in crude oil pipelines can lead to flow assurance issues, such as wax deposition and blockages, posing significant challenges for production and transportation.

Managing Wax Crystallization

To mitigate the effects of wax crystallization and ensure consistent product performance, several strategies can be employed:- Thermal Management: Controlling the temperature and cooling rates during wax processing can help regulate the crystallization process and achieve desired crystal structures.

- Additives and Modifiers: Incorporating additives, such as nucleating agents, crystal modifiers, or polymeric waxes, can influence the crystallization behavior and tailor the properties of the final product.

- Blending and Formulation: Combining different types of waxes or incorporating compatible oils or solvents can alter the crystallization kinetics and characteristics of the wax blend.

- Processing Techniques: Employing specialized processing techniques, such as shear-induced crystallization or supercooling, can control the crystal size, morphology, and distribution within the wax matrix.

- Analytical Techniques: Utilizing analytical methods like differential scanning calorimetry (DSC), X-ray diffraction (XRD), and microscopy can provide valuable insights into the crystallization behavior and aid in product development and quality control.

CONTINUE READING

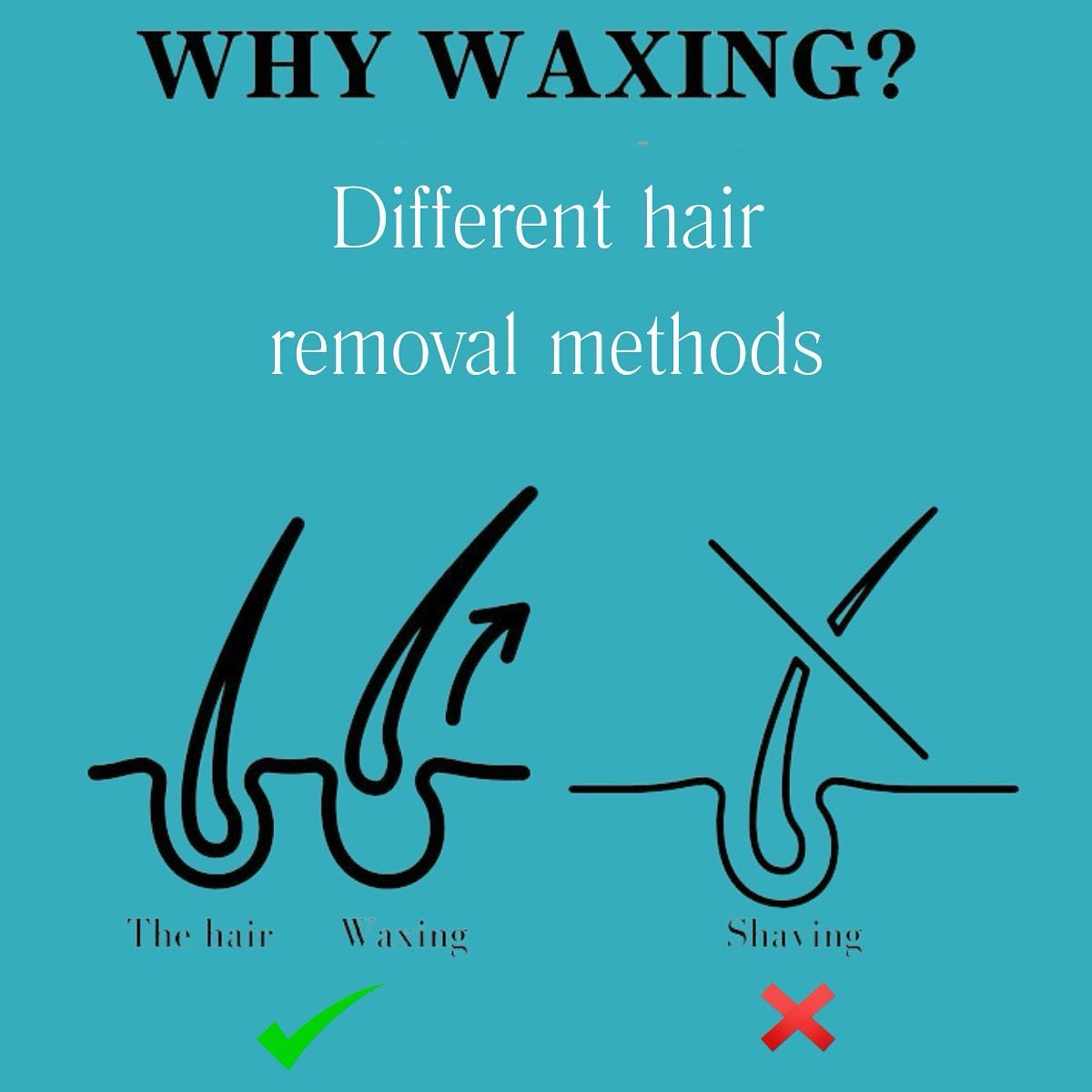

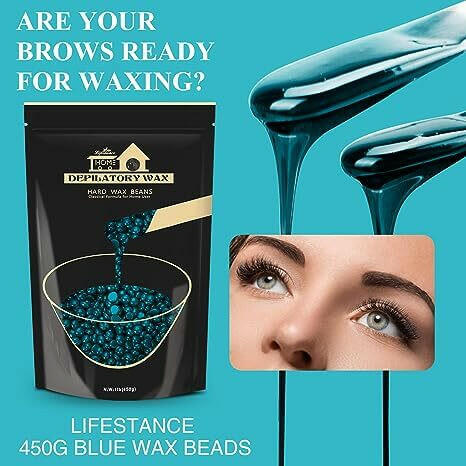

Waxing Product

Why Choose Us

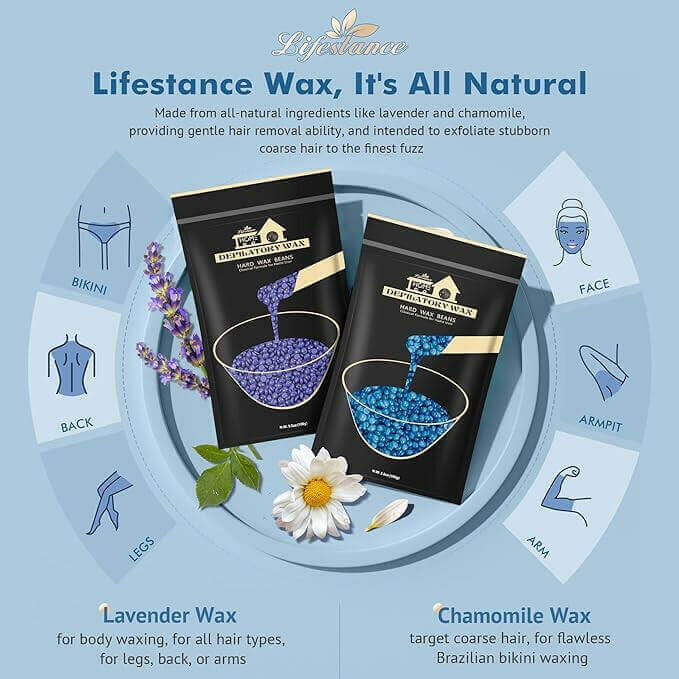

At Lifestance, we understand that everyone's hair removal needs are unique. That's why we offer a wide range of professional waxing kits to ensure that different skin types, body hair types and budgets are catered for. Whether you are a seasoned beauty professional or a first-time self-service waxer, we are committed to providing you with an exceptional product and service experience.

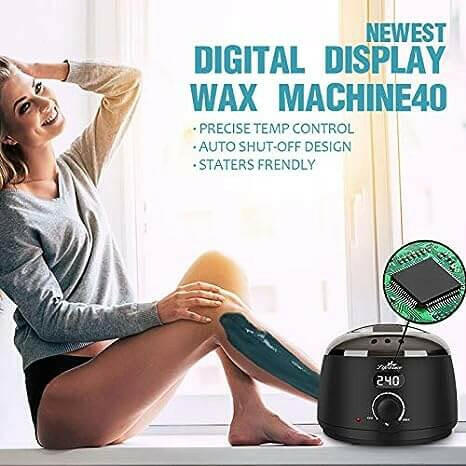

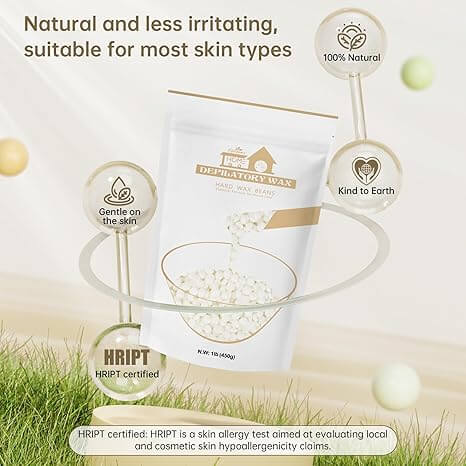

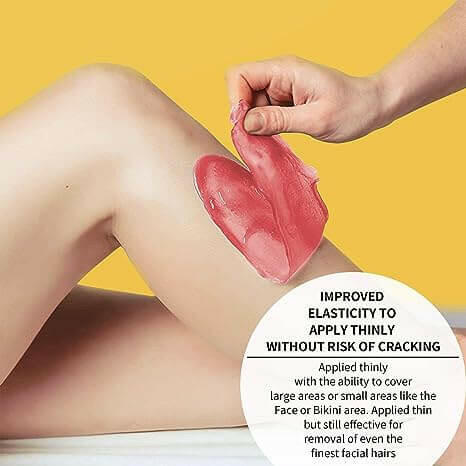

Safety and ComfortOur waxing products are made with natural and gentle formulas that have passed rigorous testing and certification to ensure that skin irritation is minimized. At the same time, our patented heating technology allows for precise temperature control, so you can enjoy a comfortable waxing experience.

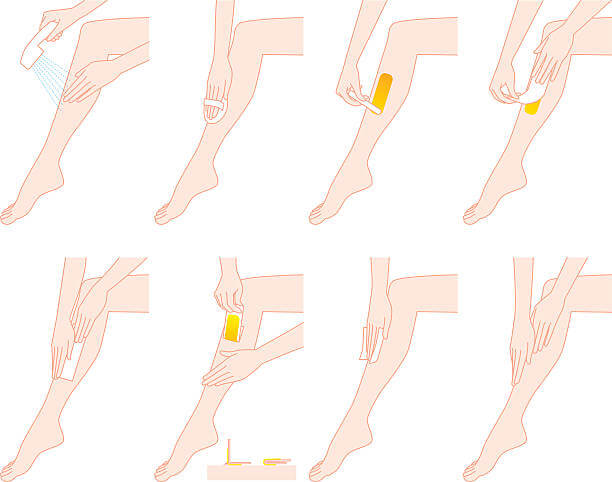

Professional Quality Convenient and PracticalWhether you're a licensed esthetician or a homeowner, Lifestance has you covered. Our kits contain everything you need and are so easy to use that even beginners can master them. The quality of our products is outstanding, ensuring smooth, flawless skin.

Innovative ideas and serviceWe are constantly developing innovative technologies and formulas to provide our customers with an unprecedented hair removal experience. Whatever your questions or needs, our team of professionals is always on hand to provide you with personalized service and guidance.

When you choose Lifestance, you choose beauty, comfort, convenience and professionalism. We are dedicated to providing you with an exceptional hair removal experience that will help you look and feel your best.